IICDC Project - 2

ARTIFICIAL INTELLIGENCE BASED PREDICTIVE MAINTENANCE (Part 2)

ADDITIONAL FEATURES :

Some additional features are also included so that the system becomes highly effective and efficient. They are as follows :1. SOFTWARE SECURITY :

As it is necessary that only the authorized users should be able to access the system, software security is considered as a very important aspect while designing. And so separate login credentials with authentication interlinks will be given to the authorized persons.

2. LOG MAINTENANCE :

Documenting the inspections and small repair helps to keep track of all the maintenance work. The system will store all maintenance records like the defects arrested by software and their details(date, time) automatically. The engineer can also include other details like date and time of repair, expenditure spent, and so on manually. It is better than paperwork. And also if needed we can print them

The following are the advantages of maintaining a log :

- Prevent expensive repair works from happening.

- It helps you create specialized maintenance programs.

- Prevent problems regarding warranty claims.

- It increases the safety of operators.

- It helps you track who is accountable for a piece of equipment.

- It increases the resale value of the equipment.

3. REMOTE MONITORING :

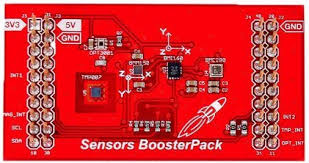

Each equipment goes under different working conditions and they have different limitations as well. Therefore, there is also a need to monitor the machine. We have used a boost xl sensor and MSP432 Launchpad as a microcontroller for vibration analysis in our project. It also measures other parameters like the gyroscope, temperature, humidity, light, pressure, etc along with the vibrations. These parameters of the working system are also important to be known as keeping equipment at optimum working condition minimizes the risk of having unscheduled downtime. Hence, we will be providing an interface that displays these parameters and helps to monitor the machine more effectively.

Boostxl sensor :

Below is the GUI of Texas instruments :

4. AUTO TRIP :

As vibrations in the dynamic system increases, the temperature gradually rises Using this relation and other conditions, we can set a temperature threshold defined by ISO standards. If for any reason the maintenance department fails to arrest the uneven conditions of the system in a given time frame. The designed product will check the temperature and all further process parameters if it goes above the threshold set then it will send an alarm and also parallelly auto trip the system (shut down's safely) before any accidents occur. Hence, the ultimate goal of the approach is to perform maintenance at a scheduled point in time when the maintenance activity is the most cost-effective and before the equipment loses performance within a threshold.

MAIN SYSTEM :

1. Login Page :

2. Prediction Page :

3. Log Page :

4. Monitor Page :

a. Temperature :

b. Pressure :

APPLICATIONS :

The system is designed to reduce industrial accidents which is basically a series of unavoidable events in an industry that results in disaster. For example, due to the chemical explosion, machine disruption due to excessive vibration, improper maintenance, or any other cause. As we say, "Prevention is better than cure".The designed system helps to prevent industrial accidents. As the system predicts the defects on the basis of vibrational pattern, it is applicable mainly to vibrating machines which show symptoms due to defect in bearings, looseness of fixtures and fittings in the chassis, or any uneven load on the shaft. Which, if not predicted in time can result in the breakdown of the machine leading to disaster.

The video below shows a small illustration of trains. The sensor can be placed near the wheels of the train. As trains travel on a steady track and if it encounters some defects like a derailment, defects in tracks it produces a different pattern. These vibrations can be sensed and analyzed so that if there is some change in the pattern, the cause can be identified and can be repaired. Also by recording the time of detection and speed of the train, the distance at which the defect was detected can be calculated.

Check the below youtube link :

Technical video :

Business video :

Post a Comment